Suit Construction Guide — Canvas vs Fused vs Half Canvas

Explained by a Professional Hoi An Tailor with 20+ Years’ Experience

Why internal construction matters more than fabric alone

When customers come to make a custom suit in Hoi An, they often focus on wool grades and colors. Fabric matters — but construction defines how the jacket behaves: how it breathes in humid weather, how the chest and lapel roll, and how long it retains shape. Two jackets in identical cloth can age completely differently depending on how the maker built the internal structure.

.jpg)

This guide explains the mechanics, the tests you can do, the real-world trade-offs, and practical recommendations for Hoi An’s climate so you pick the right construction with confidence.

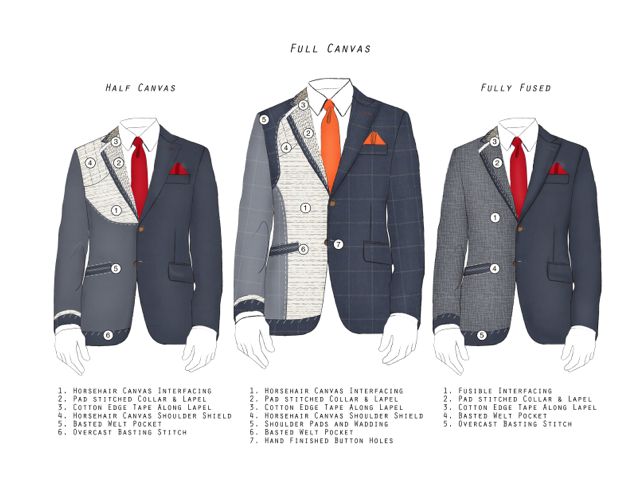

1) The three constructions — short technical definitions

.jpg)

Full canvas (full floating canvas)

A continuous canvas layer (horsehair/wool blend) runs from shoulder to hem, hand-stitched (pad-stitched) into the chest and lapel, floating from the outer cloth. It creates a living structure that moves and settles with the wearer.

Half canvas

Canvas is used only in the chest/upper front (from shoulder down to mid-torso and lapel), while the lower front may be fused or interfaced. It preserves the lapel roll and chest shape but reduces cost and tailoring time.

Fused (glued) construction

Synthetic or natural interfacing is heat-bonded to the fabric (adhesive). Quick and cheap — but the adhesive layer can de-laminate (bubble) and reduce breathability.

2) How these constructions work — physics & textile mechanics (why they behave differently)

- Canvas (horsehair/wool) is a woven, resilient structure. Pad-stitching attaches it to fabric so the canvas fibers and stitches redistribute stress; over time the canvas fibers soften and conform to body shape while keeping internal loft — this creates natural roll and resilience.

- Fused interlining uses thermoplastic adhesive. Heat bonding creates a stiff composite; humidity and repeated flex cause micro-cracks in the bond → bubbles & separation. Fused layers also reduce natural airflow between shell and lining, worsening heat retention.

- Half-canvas gives a hybrid effect: the chest and lapel get natural shaping and resilience; the fused lower front reduces cost without compromising the visually critical upper half.

3) Hands-on checks — how to verify constructions in the shop (do these tests)

.jpg)

A. Pinch / Flex test (Chest area)

Pinch inside the jacket chest and pull gently: if you feel a flexible layered structure (canvas moving slightly independent from shell), it’s canvas. A single rigid block → fused.

B. Lapel roll inspection (open the jacket)

Look along the lapel line: tiny hand-stitching/pad-stitches on the canvas edge indicate true canvas work. Machine-only glued lapels lack this subtle roll and softness.

C. Pad-stitch density (visual & tactile)

Experienced tailors use visible small diagonal stitches (pad-stitch) inside the lapel. A higher density of pad-stitches (more stitches per inch) yields a firmer, more controlled roll. Typical hand pad-stitching density ranges from 6–10 stitches per inch in bespoke work; lower density or no pad-stitching signals lower-grade construction.

D. Collar gap and roll test (fit test)

Button up or fasten the jacket and observe the collar-to-neck gap and lapel roll: canvas shoulders will show a soft natural roll and small collar gap that flattens as you move — fused collars often sit flat or spring back oddly.

E. Heat/humidity vulnerability (ask for age tests)

Ask the shop about humidity delamination history. In Hoi An’s coastal humidity, fused suits around wet seasons show bubbling sooner.

4) Durability, repairability and lifecycle (what to expect)

- Full canvas: 10–15+ years with occasional re-lining or pad-stitch reinforcement. Best long-term value if you wear suits often.

- Half canvas: 7–12 years depending on cloth and care — excellent middle ground.

- Fused: 3–5 years typical in humid climates; delamination repairs are often difficult and costly, sometimes requiring replacement of the front.

5) Cost vs. value analysis (real, not marketing)

- Fused = lowest upfront cost; acceptable for 1–2 uses or fast travel suits. Low lifecycle value.

- Half-canvas = moderate price; best value for frequent travelers who want longevity and a refined look.

- Full-canvas = highest cost and time; highest lifecycle value and ultimate fit. If your priority is an heirloom or a daily professional, full canvas is justified.

Rule of thumb: compare cost per year of use. A higher initial cost may be cheaper per year if you wear the suit often.

6) Specific recommendations for Hoi An / tropical climates

- Favor half canvas for the majority of travelers: it balances breathability, resilience, and price.

- Full canvas for clients wanting bespoke European drape and longevity. Canvas’s breathability beats fused in humid conditions.

- If choosing fused, insist on high-quality adhesives (if the shop uses them) and check warranty around humidity/bubbling; avoid fused for suits you plan to wear frequently.

7) Sewing details that matter (what pros do differently)

- Pad-stitching technique: hand pad-stitching into the canvas creates the lapel roll. Look for small, consistent diagonal stitches that attach canvas to the shell.

- Chest piece shaping: the chest canvas can be single or double layer (floating chest piece gives more depth and shape). Professional chest pieces are built in layers to control fullness.

- Armhole finishing: higher, well-set armholes increase mobility and reduce pulling—this needs skill in canvas insertion.

- Edge finishing & head canvas: boutique tailors will “hand-sew the head canvas” (the canvas shaping the shoulder and lapel) to create a soft roll line without stiffness.

8) Common shop pitfalls & how tailors mislabel constructions

- Claiming “half canvas” but placing a very thin glued interfacing that mimics canvas look. Always run the pinch test and ask to see inside the chest piece.

- Over-reliance on machine pad-stitching: machines can mimic pad-stitch visually, but hand pad-stitching feels and ages differently.

- Using low-grade canvas (cheap polyester blends) labeled as “canvas.” Ask if it’s horsehair blend or wool canvas—horsehair is traditional for loft and structure.

9) Care & maintenance to extend life

- Always dry-clean sparingly—excess solvent weakens interfacings.

- Use breathable garment bags (not plastic).

- Steam lightly to reshape lapels; avoid heavy pressing directly on canvas seams.

- Re-pad-stitch and reline when you see wear—these repairs are cost-effective for canvas jackets.

10) Quick decision matrix

- Need suit in 24–48 hours → Fused

- Want great value + durability for regular use → Half Canvas (recommended)

- Want ultimate bespoke experience and longevity → Full Canvas

FAQ

Q: Will fused suits bubble in Hoi An?

A: Yes—humidity accelerates delamination. Proper care and quality adhesives help, but fused remains vulnerable.

Q: Can fused be converted to canvas later?

A: Technically yes, but it’s almost as costly as rebuilding; better to choose canvas at purchase.

Q: How to check if a tailor’s “half canvas” is real?

A: Do the pinch test, look for pad-stitching, and ask specific technical questions about canvas type and pad-stitch density.

MAYA TAILOR HOI AN

📍 Address: 102 Trần Phú, Phường Minh An, Hội An, Quảng Nam, Việt Nam

📞 Phone: 0905992597

✉ Email: mayadesign102@gmail.com

🌐 Website: besttailorhoian.com